Then, at the end of the season, we have to “winterise” the locos, as they are not going to be used for a while. This includes several elements, so it is not a 5 minute job! Bryony and I joined one of the winterisation teams on December 29th to get our hands dirty for the last time in 2020!

Each loco had been “out”, and therefore needed the fire grate cleaning and sweeping off, the smoke box swept and emptied, the ashpan washed through and emptied, and the boiler and water tanks draining down. We needed to drain the gauge frames, lubricators, blow the condensing coils through and disconnect the pressure gauges. As I said, no 5 minute jobs here!

Breaking these jobs down, one by one:

Fire grate cleaning

One of the muckier jobs, and not for the claustrophobic, involves someone climbing into the firebox, lifting out 3 or 4 fire bars and then scraping all the ash down into the ashpan. Once all the big lumps have gone, the grate then gets swept with a hand brush, all the way round, including the brick arch, the walls and crown sheet (ceiling of the firebox). Once this has been done, the “lucky volunteer” can then exit the firebox for a well earned breather and back stretch!

Bryony sweeping out the grate of 4270 - head torch recommended

Smokebox emptying

Open up the smoke box door, and hopefully you are greeted with a nice pile of ash, right by the door, which makes it nice and easy to clean out. However, as we don't live in a perfect world, the ash has normally spread right up to the tube plate at the far end, meaning that you either use a very long broom, or, in my case, climb into the smokebox to reach and sweep it all with the hand brush. Once the ash has been removed, the tube plate needs to be brushed down to remove as much dust as possible. A hoover would make this job a lot easier!

Tom Cleaning out the Smokebox of 4270

Ashpan emptying

This job forms part of the Fireman’s list of jobs to do in the morning if the loco were going “out”. All our locos are slightly different, but they all involve going underneath with a hose pipe and washing out the ashpan, making sure there is no ash left inside them. Funnily enough, most Firemen are normally only too happy to delegate this job to their Cleaner for the day, as with some locos, it can be a VERY messy and wet affair! They then get made to shovel it all out of the pit after the loco toddles off for the day, as well.

Boiler drain down

A relatively easy job; at the bottom of the boiler, under the footplate, is the blow down valve. This has a safety bolt on it to stop it opening up when you don't want it to! Undo the safety bolt, undo the valve, and out the water goes! Done!

Water tank emptying

This is even easier, as it is just a case of making sure no one is standing too close, as they will get wet feet, then open up the feed valves for the injectors. A sure fire way to learn whether your boots are still water-proof or if you need to invest in a new pair!

Draining the Lubricator

This involves draining the water from the bottom of the lubricator, but more importantly, draining the water from the glasses. This is to stop them freezing and cracking the glasses. One glass decided it was time to retire and cracked whilst loosening the nut, so we had a quick crash reminder course on switching glasses and seals, courtesy of a very patient Jamie.

Fully drained Lubricator glasses on 4270

Condenser Coil draining down

Another easy job (so long as you’re taller than 5’5); undo both pipes, get an airline and blow it through the coil. Best to make sure you are not standing underneath it though, as you will get an impromptu shower, which in December is not very welcome!

Pipes split and drained on 4270’s Condenser Coil

Pressure Gauge drain down

Although technically no water should get to the Boiler Pressure gauge and the Steam Heat gauge, it is good practice to take the pipe off the bottom of these gauges, so that any water that may have accumulated is released. Water has a habit of hiding in nooks and crannies, and our owning groups may have something to say if something decided to run afoot over the next few months!

Pressure Gauges on 4270 with pipes released

Gauge Frame drain down

Another easy job! Ensuring that the frame has been isolated from the boiler, take the Gauge Frame cover off (easier said than done for some people!), then slacken the top and bottom nuts off, and the glass should then move enough to ensure there is no trapped pressure.

Gauge Frame on 4270, cover removed and nuts slackened

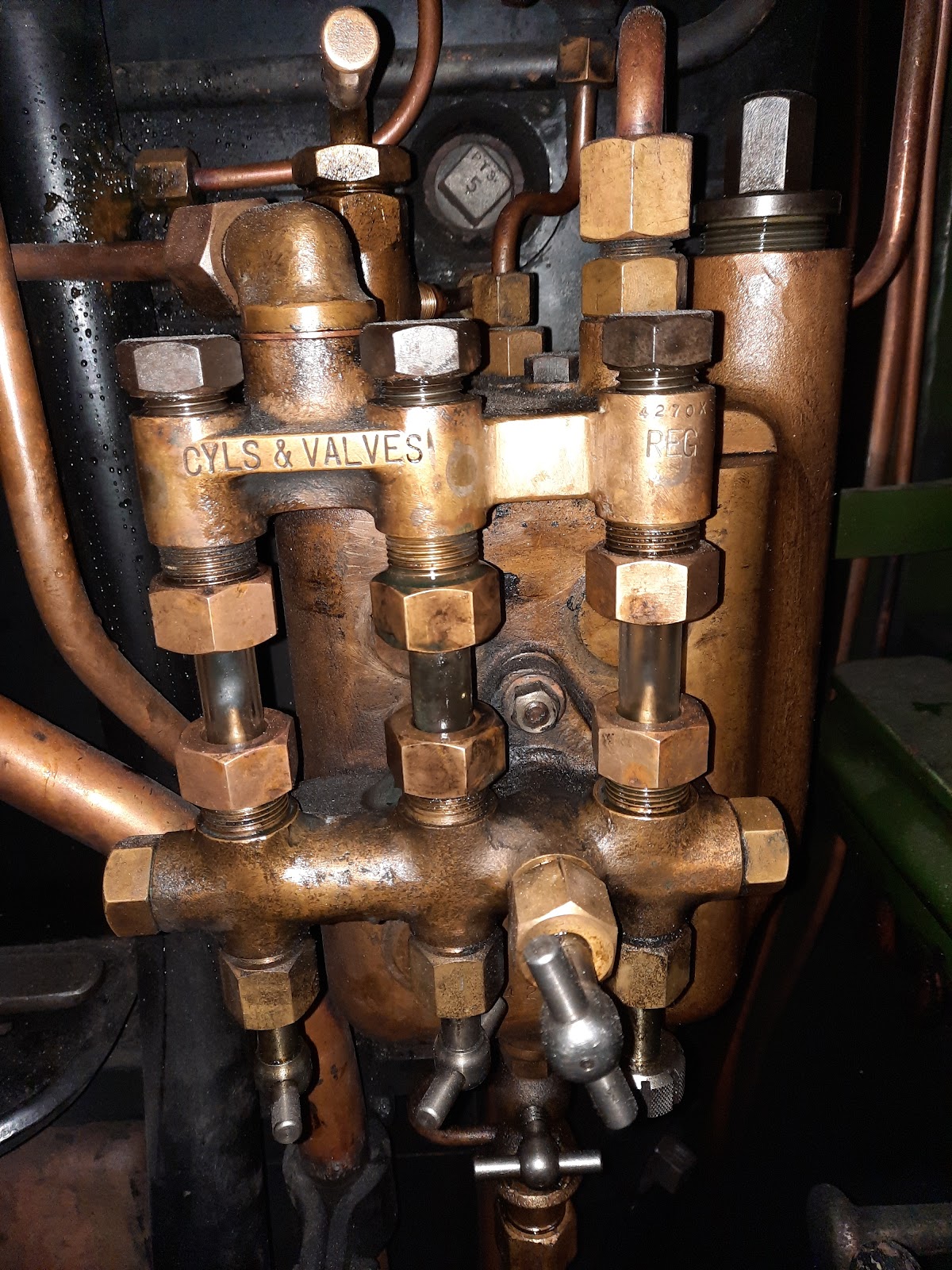

Masons Valve repair

One of our firemen had booked a problem with a steam leak from the Masons Valve, so while we were on the footplate, we thought we would take the opportunity to try and rectify the fault.

It turns out that the Masons Valve on 4270 is in fact just for show (sshhh, don't tell anyone), and doesn't actually have any working parts inside it. We took the bottom of the Masons Valve and found that there was a small hole in the blanking plate, which was letting steam past, under pressure. The decision was taken to put the bottom casting of the valve on to the diamond miller, and flatten back the surface to get a much better seal. Jamie then put it all back together, using some “Steam tight” on the threads, and back on the loco. This will be monitored the next time the loco is in steam, to see if the leak is still present.

The bottom casting off the Masons Valve, taken off and milled, then refitted by Jamie

Fusible Plug repair

4270 had also been “red carded” on Christmas Eve, which meant that it was no longer fit for service, due to having a very small steam leak in the crown sheet of the firebox. This only manifested itself when the boiler was under pressure, so anyone lighting the loco up would not be able to see it.

Jamie took the plug out, after marking where the leak was coming from, so it can be repaired and reinstalled.

Fusible plug (left) and the hole in the Crown Sheet where the plug has come out from. The yellow mark denotes where it was leaking. Note the telltale marks in the dust in the area around the leak

With the current situation, only essential maintenance is currently allowed at Toddington, so who knows when we can report on more work being undertaken!

Any questions, feel free to ask them in the comments, and we will do our best to answer them

Thanks for reading

TTFN

Tom